Closed Ampoule Filler and Sealer

LODHA is serving different industries like pharmaceutical, chemical, biotechnology, cosmetic, and the veterinary industry for long. We understand the customized requirements of each of them. Hence, we have designed the LI – AFS C machine. The Closed Ampoule Filler and Sealer Model LI-AFS C comes in both standard and customized models and used for filling and sealing of type D pre-sterilized closed ampoules. The machine has an inbuilt mechanism of “no ampule no filling” characteristics to keep the filling safe and secure. It works on the principle of slant travel of ampoules and is designed to take care of the wide variation of ampoule neck dimensions, thicknesses of available standard ampoules. The machine is of low cost and high quality designed to keep your operational cost below the threshold limit.

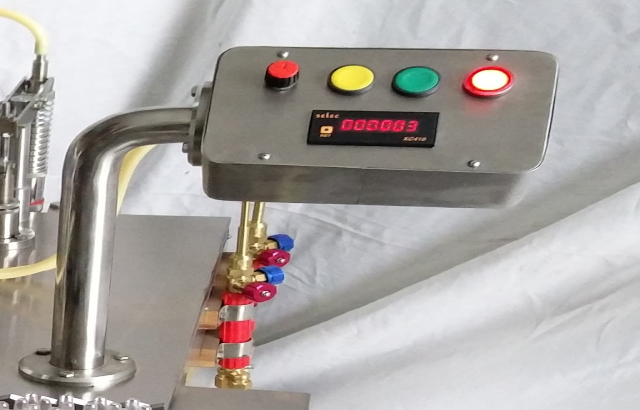

The Ampoule filling and sealing machine is built on a stainless steel square pipe frame and encompassed with stainless steel coverings. It is cost-effective, efficient, and required less maintenance. The pleasing matt finish will hide the ruggedness of the system. Further, the large opening section is specially designed at the front end bottom side of the machine for easy cleaning. The pendant type electrical control panel is lifted from the machine for ease of operation and safety. The machine is suitable for Ampoule Filling in pharmaceutical, cosmetic, agriculture, and chemical industries.

The Salient Features of the machine are:

- Compact GMP model.

- Suitable for filling and sealing of type ‘D’ ampoules.

- All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

- Minimum change over parts from 1ml to 10ml ampoule size.

- "No Ampoule - No Filling" system.

- Ampoule neck centering during gas flushing and filling operations.

- Possibility of nitrogen gas flushing before, during, and after filling.

- Full accessibility allows for easy maintenance.

- Machine equipped with a pre-warming station.

- Minimum change over time, little maintenance & easy cleaning.

D Type Closed Ampoule

The machine comes in three models, single head, two head, and four heads. The production output of the three types ranges between 15 to 100 D Type Closed Ampoule per minute. The operation of the machine required 1 Kg. /cm2 oxygen and nitrogen pressure. Pre-Sterilized ampoule tray gets directly loaded into to slant hopper of the machine. The magazine type cassette delivers closed ampoules on moving eccentric ampoule rack in the batch of one/two/four. Ampoule rotating lever rotates the ampoules and extreme pressure of the gas heat the ampoules. The ampoule opening process is done by the manner of pre-heating and opening with the pressure of the gas (LPG + oxygen). During the stoppage of rack sequentially ampoule opening, pre-gassing, filling, post gassing, pre-heating, and final sealing is achieved. Filled & sealed ampoules are collected automatically in SS tray in an upright position without hand touch.