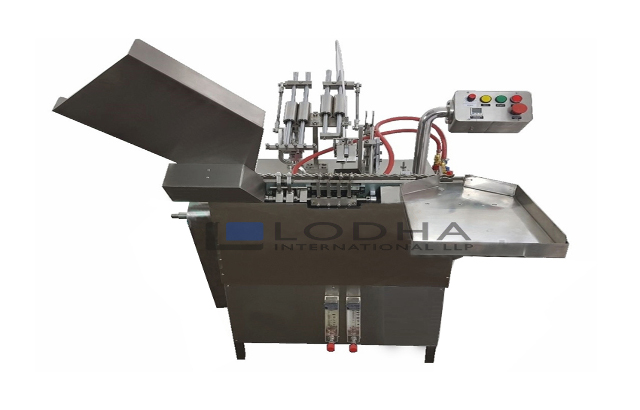

Glass Ampoule Filling and Sealing Machine

LODHA is serving the pharmaceutical, biotech, cosmetic, veterinary & chemical industries with its quality ampoule filling machines. We have designed machines that can address the customized need of these industries. On a similar line, LODHA has developed Automatic Glass Ampoule Filling & Sealing Machine to fill and seal the ampoules. The machine is designed in such a way that it can accommodate the different needs of different industries. Both the standard model of as well as its custom made models comes with the assurance of LODHA. The machine operates on the principle of slant travel. While filling and sealing, it can accommodate and take care of the wide variation of ampoule neck dimensions, thicknesses, and ovalness of available ampoules.

The machines are developed on the Stainless Steel square pipes frame & encompassed with Stainless Steel coverings. The machine will land in your factory premise with a pleasing matt finish design. It works with the filling accuracy of +/-1% using Oxygen and LPG as gas for sealing. At the bottom of the machine, a large open area has been configured to assist in cleaning and maintenance of the machine. The pendant type electrical control panel is lifted from the machine for ease of operation and safety.

The Salient Features of the machine are

- The machine has the Compact GMP model.

- The assured production output is 30 ampoules/minute which can be increased to 150 ampoules/minute.

- All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

- The machine is suitable to fill 1ml to 20ml ampoules

- Minimum change over parts from 1ml to 20ml ampoule size.

- The machine has an in-built "No Ampoule - No Filling" system.

- During the gas flushing & filling of ampoules, their neck gets auto centralized. Possibility of nitrogen gas flushing before, during, and after filling.

- Full accessibility allows for easy maintenance.

- Machine equipped with a pre-warming station.

- Minimum change over time, little maintenance & easy cleaning.

Glass Ampoule Filling and Sealing Machine Manufacturers

LODHA is specialized in ampoule filling and sealing machines. We are the Glass Ampoules filling and sealing machines manufacturers who also have an in-house design and development team for developing new machines. Our designs make machine operations smooth. The sterilized ampoule tray directly loaded into to slant hopper of the unit. The Synchronized star wheel delivers ampoules one by one on moving eccentric ampoule rack in single/two/four/six. The machine works on 1 Horse Power. With four heads, it can handle 1 to 10 ml. ampoules. During the stoppage of ampoule on the slant rack, the process of pre-gassing, filling, post gassing, pre-heating, and final sealing is sequentially achieved. The filled and sealed ampoules then collected on the collection tray automatically without hand touch.

The machine is designed to perform the following operations:

- Ampoule feeding by in-feed hopper, star wheel, and ampoules transfer into transport rack.

- With every machine stroke, two ampoules get filled and advanced.

- Auto centralization of ampoules necks during pre-heating, post-heating, gas flushing, and liquid filling.

- Rotation of ampoules neck in the preheating and heating station.

- Elimination of burdened-off ampoule tips by clippers and ejection into a separate container.